Wall Thickness command

Use the 3D Print tab→Validate group→Wall Thickness command  to identify areas (faces) of a 3D model where the wall thickness is insufficient for 3D printing. Wall thickness is defined as the minimum thickness your model should have at any time. For example, you can use this command to validate the wall thicknesses of an imported mesh model, or to determine whether parts created with web networks meet the requirements for polymer plastic molds.

to identify areas (faces) of a 3D model where the wall thickness is insufficient for 3D printing. Wall thickness is defined as the minimum thickness your model should have at any time. For example, you can use this command to validate the wall thicknesses of an imported mesh model, or to determine whether parts created with web networks meet the requirements for polymer plastic molds.

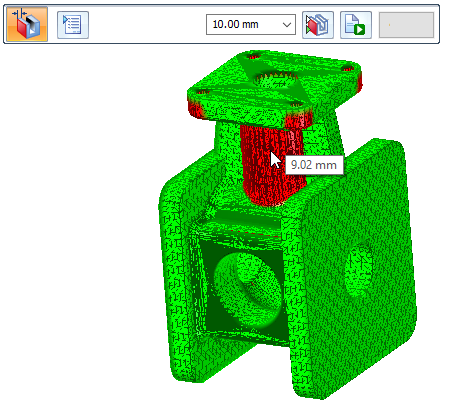

Use the Wall Thickness command bar to perform the analysis based on the Minimum Thickness value required by the 3D printer. When you click the Calculate button, the analysis returns a highlighted color display of all faces that have less than the minimum thickness (default color=red). All faces having more than the minimum thickness display as green (default color).

Wall thickness calculation

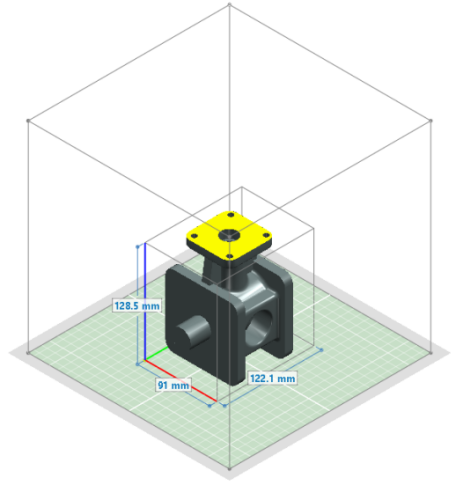

The wall thickness is always calculated parallel to the print bed. By default, the print bed is in the X-Y plane. Therefore thickness is calculated in the X and Y direction.

Any walls having lesser thickness in the Z-direction are not considered as not meeting the minimum thickness value.

The Application menu→3D Print page shows the model document on the X-Y plane of the printer bed, where X (red axis), Y (green axis), and Z (blue axis).

© 2021 UDS